There comes a time...

...when one feels the need to alter course. Russell and I started PT Watercraft in 2009, to create an outlet to share Russell’s vision for a really good nesting dinghy. Since then, he has built 8 boats to define the build process, take the right photos and to update the manuals. A major revision of the PT11 and Spear manuals has only just been completed. He has also built parts for approximately 175 kits, including 130 for the PT 11 nesting dinghy.

By Intention, our business model has been a small and custom operation. We are more creative in nature than business minded, so expanding to include employees and larger production has not attracted us. Instead, we have farmed out many aspects of our production to the abundant local talent found in Port Townsend.

The level of detail and care put into each kit has earned us a reputation that we are proud of: that our kits take the kit concept to a higher level than others, at a price, but at excellent value for the money. Unfortunately, this is also a business model that is difficult to sell. Yes, when we started, we thought we’d create the business and eventually sell it.

What we find is that with open ended shipping dates, we never seem to get ahead of stocking parts and getting kits out the door. There are no gaps between for writing books that we have promised our book customers, nor to develop new ideas. By re-organizing our shipping schedules, we hope to reserve time for these creative endeavors. This might mean fewer kits produced but our level of quality and service would remain high.

What are the actual changes at PT Watercraft?

We have had to raise our prices. This was a really hard decision for us. In an effort to keep our prices in some sort of league with similar sized boats, we have never paid ourselves very well for the labor intensive product we produce and materials and shipping costs just keep going up. On the other hand, we are not willing to ship a lesser quality product.

Because most of our kits are sold in Fall and Spring, we are considering to restrict shipments to specific time frames within those seasons. Deposits accumulated in Summer and Winter will largely dictate the number of kits we ship.

We are suspending all exports. Exporting has always cost us more with extra paperwork and materials (heavy duty crates, for example). Customers abroad pay increasingly more for shipping and import duties. It just does not feel right and we sincerely apologize to those outside of the US who were hoping to get a PT 11 kit. Canadians can make a road trip of it or we can ship to bonded shippers on our side of the border.

What is NOT changing?

Our customers are really important to us. We are here for you and will continue to work through this transition. We are dedicated to good service and creating the nicest kits we possibly can.

Please follow our blog as we trial new arrangements. Our home page now has a clear explanation of what makes our kits special. Further details are continued on the PT 11 homepage. The website may appear a bit haphazard for a while. I am shuffling things around and trying to simplify it all.

Thank you for your patience and support.

Ashlyn & Russell Brown

March 1, 2019

As per our new homepage: the full text: by Russell Brown

Understanding the PT 11 nesting dinghy

There are many nesting dinghy kits available, but our PT 11 dinghy kit is a bit different.

Because our kits are quite expensive, we would like to offer some explanation. We would also like to make sure that our kit’s are an appropriate choice for anyone thinking of building one.

We are long-time designers and builders of high-performance sail boats. Nesting dinghies have been a passion for more than 40 years, during which time our study of the compromises and possibilities have been a bit of an obsession. Many prototypes have led to the kits that we now offer.

Could we have created a simpler and more affordable boat? Of course we could have, but it wouldn’t have the qualities that make the PT 11 such a great boat.

What features make this boat special?

The ability to assemble and disassemble the boat in seconds, in the water or out of the water. The unmatched strength of the assembled boat, a challenge in nesting dinghy design.

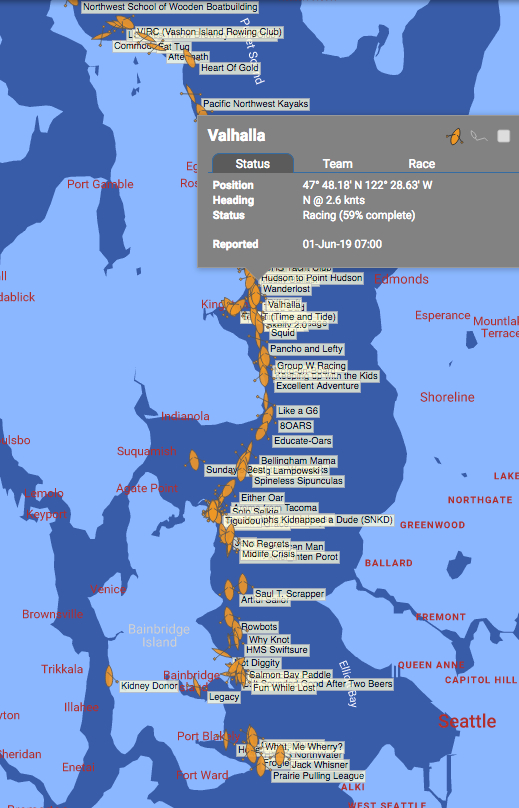

The rowing performance of our boats is quite amazing. One was used in a 70 mile endurance race last year, finishing in the top third of a 120 boat fleet in under 20 hours, surprising for an 11 foot dinghy. An outboard motor is quite unnecessary when using the boat as a tender.

The sailing performance is very good. The stock foils (machined daggerboard and kick-up rudder) help the boat sail upwind like a 12 meter. The rig is the lightest and easiest to use dinghy rig on the market. The two-piece carbon mast and boom, sail, and all rigging weigh just 10 1/2 pounds, store in a small bag, and assembles in minutes, making a quick sail in a new anchorage easily done.

Other prominent features include a large truly watertight storage area, sealed flotation tanks fore & aft, and a very dependable daggerboard trunk cap that allows towing in rough water and at high speeds. Two rowing stations and multiple foot brace positions allow keeping level trim with multiple passengers and allow rowers of different heights.

These qualities are combined with many other well-thought-out features, some that make construction easier and many that make the boat easier to use, lighter, and more efficient.

What do we not like about the PT 11? It’s complex. While we have not over-engineered this boat and we continually work on making the build simpler, a really good nesting dinghy, especially one that could last forever, requires complexity. Much of that complexity is on our end. We manufacture many custom parts for the boat and we aren’t shy about expensive alternatives.

The fact that we have sold so many kits for the PT 11 with almost no advertising says a lot.

Builders of the 11 see the value of the kit, the manual, and the finished product. Resale values of well built PT 11’s also point to a well conceived product.

Is the PT 11 for you? If you are attracted to the boat and it fits your needs, then maybe. Are you right for the PT11? Probably, if the next sentences work for you.

If you want the performance that our kits offer and aren’t afraid to put in the effort and time required, if you look forward to a good winter or summer project, and are willing to carefully follow a very detailed building manual.

Building a boat can be a very satisfying and rewarding experience; an experience that is increasingly missing in modern times. We ask a lot of our builders, but they get a lot in return. They get the experience, a new set of skills, and in the end, they get a very versatile boat.

Because we have very high standards for what we want in a boat, we start with the best materials:

We hand pick through units of high grade Okoume plywood to find the best looking and flattest panels of five different thicknesses of plywood. This doesn’t mean it’s always perfect, but we choose the best available and it’s a wonderful material for this type of boat. Most of the plywood parts are CNC machined, but many of them are post-machined to bevel and round edges where appropriate. The lumber parts kit (foredeck stringers, glue cleats and reinforcements) are machined from high-grade Sitka Spruce. The foot braces, oarlock riser blocks, and back seat cleats are machined to a ready-to-finish level from Sapele mahogany.

We supply the best glass cloth of 3 different weights to protect and reinforce, while keeping the boat as light as possible.

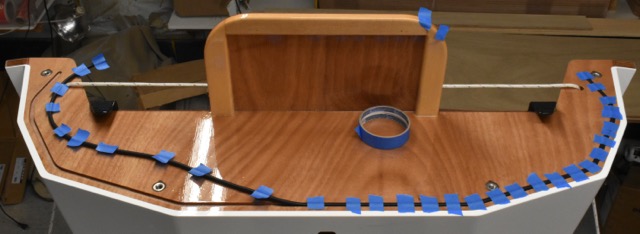

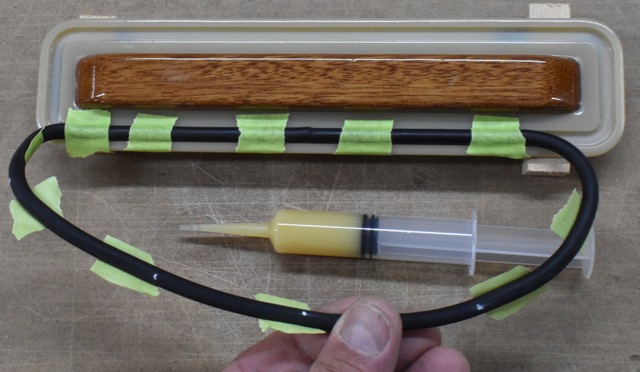

Carbon fiber alignment clips, goose-neck fittings and fiberglass mast sockets are molded “in house”.

The foils are CNC machined from carefully selected Okoume plywood (2 layers of 12 mm Vacuum bagged together on a “flat table”) to make NACA section foils of almost 1” thick. For the weight and performance offered by these foils, they are relatively very affordable and not difficult to finish.

The machined 316 stainless connective hardware is machined by Paul Zeusche, an expert local machinist and boat builder. This hardware constitutes a large part of the value of the kit and is continually fine-tuned. We are extremely lucky to have some very smart friends.

The masts and booms are made in state by ICE, a maker of the highest quality carbon fiber tubes on the planet. The two-part mast and boom (almost 23 lineal feet of tapered custom carbon tubes) weigh just 6.7 lbs and that includes all the hardware and running rigging on the boom (5 Harken blocks, 2 snap hooks, 1 s-hook, 7 eye straps, 1 cleat, 37 feet of running rigging, and a goose-neck fitting.)

Many other parts and pieces are produced in our shop or locally. Besides the plywood, which is made in France, just about everything in one of our kits is made in the US.

The most valuable single piece of the kit is the building manual. We don’t encourage people without hand tool experience to build our boats, but the manual allows someone with no epoxy or boat building experience to build a really good boat.

It’s just the two of us running PT Watercraft, which means we can offer very good quality control and economy,

We are now completing our 8th PT 11, built to improve the manual and fine-tune the kits (as were the other 7). We do this so that our builders can get the most value, pleasure, and longevity from their boats. The kits and manuals for the PT 11 and PT Spear are getting better every year.

We have also been working on a video series with Off Center Harbor, showing the more technical parts of building a PT 11. These video’s will be available free to our builders. We hope builder will follow the blog for important updates.

Featured comment from March 2019: “ I would like to reiterate one point as far as the value is concerned: I've yet to float in my boat, but I'm confident it will work as designed. The money spent was worth it, just to have "taken the class" on working with epoxy, and stitch and glue boat building, getting a sweet boat at the end is of course a nice bonus. The manual describes such nuance of technique, I feel like an expert, despite limited experience with epoxy and glass. That said by a working guy on a budget.” A.S. Stowe Vermont

...